Wireless Engineering & Project Management

KM Consulting Engineers, Inc., a dynamic and versatile engineering firm, operates out of Central New Jersey, offering expertise across civil, structural, electrical, and telecommunications engineering. With a deep commitment to Cellular/PCS technology, KM Consulting Engineers has positioned itself as a leader in telecommunications design, project management, and installation. Our innovative solutions have established industry benchmarks that others in the field now emulate. Backed by extensive experience in non-destructive testing for tower foundation and innovative reinforcement, we bring specialized knowledge to the design of caissons, helical piers, and micropiles for both tower and building projects.

Our Mission

Our mission is to exceed client expectations through precise project planning, focused project management, and an unwavering commitment to quality and timeliness. This dedication to high standards, attention to detail, and reliable deliverables has earned us recognition and respect from clients and competitors alike.

Water Tank Cell Sites

Wireless companies prefer mounting antennas on water tanks due to their height, location, and strength. However, conventional welding to attach mounts can damage the tank's internal epoxy paint, which protects drinking water from contamination. Alternative methods like adhesives and mechanical attachments often don't meet structural requirements, leading KM Consulting Engineers to explore capacitor discharge stud welding, a low-heat welding process that avoids damaging the paint. Testing confirmed this method as safe for the epoxy coating and structurally sound for antenna mounts, allowing wireless equipment to be attached securely to water tanks without compromising water quality.

Innovative Tower Reinforcement

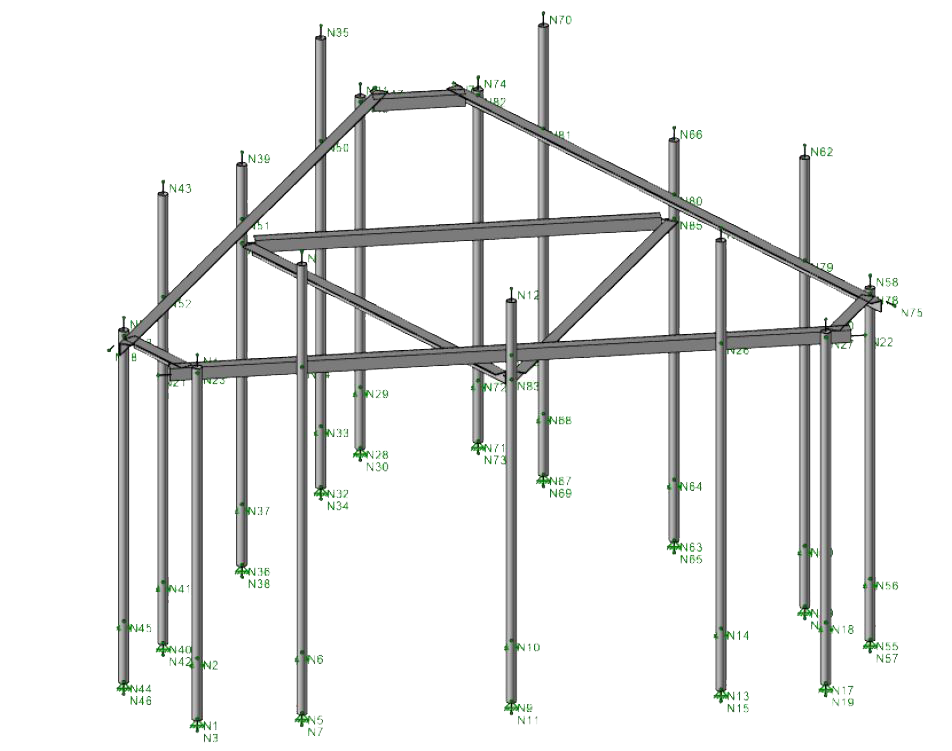

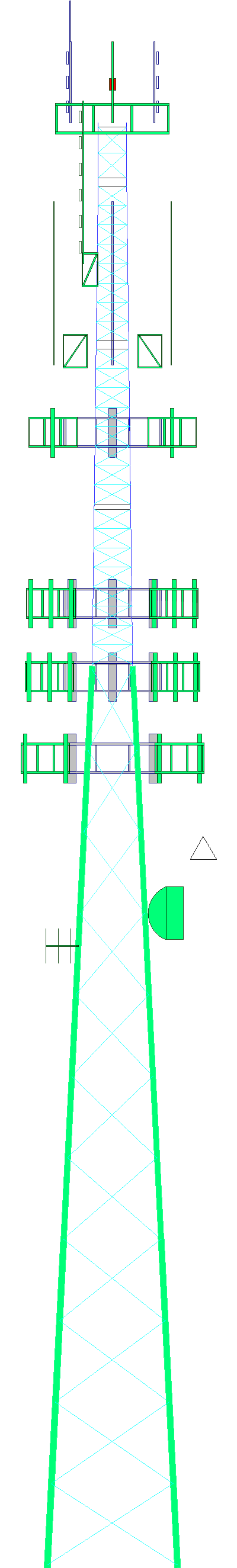

To reduce the need for new tower structures, communities are implementing codes to prioritize co-location on existing towers. However, co-location often reveals that many towers cannot support additional loads due to outdated standards and neglected maintenance, leading to overstressed structures. Over time, owners have added equipment without structural analysis, worsening the issue. Solutions include removing obsolete equipment, reinforcing overstressed components, and a new method: composite column reinforcement, which involves injecting structural grout into hollow tower legs for added strength. This approach, although effective for moderate overstressing, requires skilled contractors and careful preparation but offers a cost and time effective alternative to traditional reinforcement methods.